Categories

Tags

-

#Peristaltic Pumps

#Micro Peristaltic Pump

#Peristaltic Pump Head

#Straight Tubeline Peristaltic Pumps

#Peristaltic Pump Tube

#Peristaltic Pump

#Cummins Engine

#Silicone Tube for Peristaltic Pump

#Why Multichannel Peristaltic Pumps Are Essential for Laboratory Automation

#Technologies For Jewelry

#Silicone Tubing Peristaltic Pumps

#OEM Peristaltic Pumps

#Silicone Tube for Your Peristaltic Pump

#Handheld Sampling Pump

#The Benefits of Using Peristaltic Pumps in Food and Beverage Applications

#Medical Grade Silicone Tubing

#Large Peristaltic Pumps

#Cummins Engine Cylinder Head

#Industrial Peristaltic Pump

#Low Flow Peristaltic Pumps

#Peristaltic Pump Motor

#Industrial Peristaltic Pumps

#Peristaltic Pumps in Industrial Washing

#3D Printed Peristaltic Pump

#Peristaltic Pump Silicone Tube

#Multichannel Peristaltic Pump

Archives

3D Printed Peristaltic Pump: Design, Working Principle, and App

-

3D Printed Peristaltic Pump: Design, Working Principle, and Applications

In recent years, 3D printing technology has revolutionized the way mechanical components are designed and prototyped. Among its many innovations, the 3D printed peristaltic pump stands out as an affordable, customizable, and efficient solution for small-scale fluid control. Combining the simple yet effective pumping principle of traditional peristaltic pumps with the flexibility of additive manufacturing, these pumps are now widely used in laboratories, DIY projects, and educational settings.

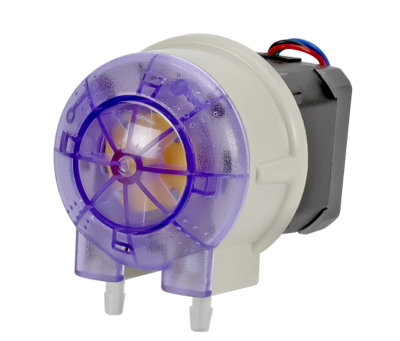

A 3D printed peristaltic pump is designed to transfer fluids through a flexible tube using mechanical compression, just like industrial peristaltic pumps. However, instead of expensive machined components, most parts are printed from plastic filaments such as PLA or PETG, making it lightweight, inexpensive, and highly customizable.

Working Principle of a 3D Printed Peristaltic Pump

The operating principle of a peristaltic pump—3D printed or otherwise—is inspired by biological peristalsis, the way our digestive system moves fluids. The pump works by squeezing a flexible tube with rollers that rotate in a circular motion.

Here’s how it works step by step:

1. A motor drives a rotor equipped with several rollers.

2. As the rotor spins, the rollers compress the flexible tube in sequence.

3. The compression pushes the fluid forward, creating a continuous flow.

4. When the rollers release, the tubing returns to its original shape, drawing in more fluid.

Since the liquid only contacts the inner surface of the tube, contamination is minimal—making the design suitable for handling sensitive or sterile fluids such as biological samples or chemical reagents.

Design Overview: Components and Materials

A typical 3D printed peristaltic pump consists of three major sections:

l Pump housing – Holds the tube and rotor assembly in place.

l Rotor and rollers – Usually 3D printed; can include bearings or printed cylinders that compress the tubing.

l Flexible tube – Usually made of silicone or Tygon for elasticity and chemical resistance.

l Drive system – A DC or stepper motor that ensures smooth, adjustable rotation.

3D Printing Materials:

l PLA: Easy to print, ideal for educational or experimental setups.

l PETG: More durable and heat-resistant.

l ABS or Nylon: Suitable for slightly higher mechanical loads.

Designers can easily customize the number of rollers, tube size, and housing shape using CAD software, allowing precise control over the flow rate and pressure. Some advanced designs even integrate 3D printed gears or magnetic couplings for improved performance.

Advantages of 3D Printed Peristaltic Pumps

3D printed peristaltic pumps offer a range of benefits that make them particularly useful for non-industrial or research environments.

Low Cost:

Printing the components costs just a few dollars, making it ideal for budget-conscious labs or students.Rapid Prototyping:

You can design, print, and test a new pump prototype in less than a day—far faster than ordering or machining parts.Customizable Design:

Flow rate, tubing diameter, and roller configuration can be modified for specific experimental needs.Clean and Contamination-Free Operation:

Fluids are fully enclosed in the tubing, reducing cross-contamination risks.Compact and Portable:

Lightweight 3D printed bodies make the pump suitable for integration into small instruments and mobile systems.Educational Value:

Perfect for demonstrating fluid mechanics, biomedical concepts, and engineering design in classrooms or workshops.Limitations and Challenges

While 3D printed peristaltic pumps are innovative, they are not without drawbacks.

l Limited Durability: Plastic components wear faster than metal or high-grade polymer housings.

l Low Pressure Capability: Suitable for low-flow, low-pressure applications only.

l Chemical Compatibility: Some filaments are not resistant to organic solvents or acids.

l Accuracy and Repeatability: Flow stability may vary slightly compared with commercial-grade pumps.

For critical or industrial use, it’s best to choose professional-grade peristaltic pumps designed for continuous operation and chemical resistance.

Applications of 3D Printed Peristaltic Pumps

Because of their flexibility and low cost, 3D printed peristaltic pumps are popular across multiple fields.

1. Laboratory Research

Controlled dosing of reagents or buffers

Microfluidic or analytical chemistry setups

Biological sample transfer without contamination

2. Educational Demonstrations

l Teaching fluid dynamics or mechanical design

l Demonstrating peristaltic motion in biology classes

l Building affordable lab equipment for STEM learning

3. DIY and Maker Projects

l Home-built automatic plant watering systems

l Small beverage or liquid dispensers

l Prototype coffee or cocktail machines

4. Prototyping and Design Testing

Engineers can rapidly validate new pump concepts.

Useful for early-stage product development before moving to injection-molded or machined components.

Future Development

As 3D printing materials and techniques advance, we can expect stronger, more chemically resistant, and more precise 3D printed peristaltic pumps. Integrating smart sensors, stepper motor control, or IoT monitoring may soon make these devices capable of semi-professional use.

Open-source projects are also driving collaboration across the maker and research communities, democratizing access to fluid handling technology.

Conclusion

The 3D printed peristaltic pump represents the perfect balance between simplicity, accessibility, and functionality. It enables students, researchers, and innovators to experiment with fluid control systems without high costs or manufacturing barriers. While it cannot yet replace industrial peristaltic pumps in demanding applications, it plays a vital role in education, rapid prototyping, and DIY innovation.

For industries or laboratories requiring precision, durability, and consistent flow performance, upgrading to a professional OEM peristaltic pump is recommended.

JIHPUMP provides reliable peristaltic pump solutions suitable for laboratory automation, food dispensing, and fluid sampling applications.