Aluminum Powder as a Key Material in Semiconductor Fabrication

-

Aluminum Powder as a Key Material in Semiconductor Fabrication

Introduction

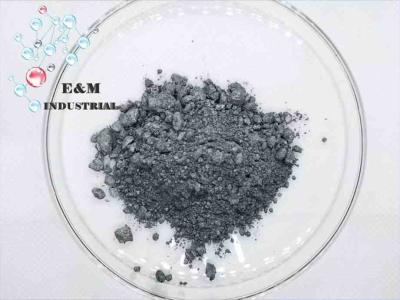

In the fast-evolving electronic semiconductor industry, the demand for high-performance, miniaturized, and reliable components has never been higher. Achieving these goals requires the use of advanced raw materials with exceptional purity and stability. Aluminum powder has emerged as a critical material in semiconductor fabrication, contributing to processes such as electronic ceramic sintering, semiconductor packaging, and functional doping.The Role of Aluminum Powder in Sintering

Sintering is a fundamental process in semiconductor manufacturing, particularly in producing electronic ceramics and components like capacitors and substrates. Aluminum powder, when used as a reducing agent or sintering aid, helps optimize the densification process. Its high reactivity and controlled particle size allow manufacturers to achieve uniform microstructures, reduce porosity, and improve the overall electrical performance of sintered components. This is particularly crucial for applications requiring high thermal conductivity and low dielectric loss, such as power semiconductors and multilayer ceramic capacitors (MLCCs).Aluminum Powder in Semiconductor Packaging

In semiconductor packaging, aluminum powder plays a vital role in improving thermal management. Packages that incorporate aluminum-based conductive fillers or alloys can efficiently dissipate heat generated by high-performance chips, ensuring long-term reliability. Additionally, aluminum’s compatibility with other metallic elements, such as magnesium in Mg-Al alloys, allows precise tailoring of mechanical and thermal properties, which is essential for maintaining package integrity under extreme operating conditions.Functional Doping and Performance Enhancement

Beyond sintering and packaging, aluminum powder is also used as a functional dopant in certain electronic materials. By carefully incorporating aluminum into semiconductor ceramics or high-molecular matrices, manufacturers can modify electrical conductivity, enhance flame retardancy, or fine-tune other functional properties. For instance, aluminum doping can help create defect-controlled structures in ceramic layers, improving the component’s performance stability and reducing failure rates in high-frequency electronic devices.Why High Purity Matters

The effectiveness of aluminum powder in semiconductor applications relies heavily on its purity and particle uniformity. Impurities can lead to unwanted reactions, structural defects, or inconsistent electrical properties, which could compromise the performance of the final product. Partnering with a reliable supplier ensures access to high-purity aluminum powders that meet stringent semiconductor industry standards, providing manufacturers with confidence in both process control and end-product quality.E&M Industrial Limited: Your Trusted Supplier

E&M Industrial Limited specializes in supplying high-purity chemical raw materials to the semiconductor industry. Our aluminum powders, magnesium-aluminum alloy powders, and other advanced chemicals are designed to support cutting-edge electronic components with precise performance and consistent quality. With a stable supply chain and a commitment to excellence, we provide the material foundation that allows semiconductors to achieve higher efficiency, smaller form factors, and improved reliability.Conclusion

Aluminum powder is more than just a raw material; it is a key enabler for high-performance semiconductor manufacturing. From enhancing sintering processes to optimizing thermal management and functional doping, its role is indispensable in the production of advanced electronic components. By sourcing aluminum powder from a trusted supplier like E&M Industrial Limited, semiconductor manufacturers can ensure their products meet the rigorous demands of modern electronics.